MINIMISING ENVIRONMENTAL IMPACT ON OUR COMMUNITIES

The Company is dedicated to mitigating the negative impact of our developments. We are also committed to complying with all applicable EHS legal requirements enforced by local authorities, such as BCA, National Environment Agency (NEA), PUB, the Ministry of Manpower (MOM) and the Singapore Civil Defence Force (SCDF). Through constant monitoring, evaluation and auditing of our ISO 14001 and ISO 45001-certified EHS management systems, the Company actively ensures that all our activities and operations comply with existing regulatory requirements.

Managing Water Discharge at Construction Sites

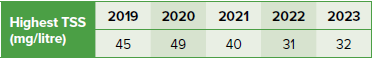

The discharge of wastewater into the public sewerage system and open drains, canals and rivers are strictly regulated by PUB and NEA. To ensure that Total Dissolved Solids (TDS) and Total Suspended Solids (TSS) readings of the discharged water do not exceed the legal limit of 1,000 mg/litre and 50 mg/litre respectively,1 the Company works closely with all our contractors to track the quality of water discharged into public sewerage and drainage systems. At all our construction sites, Earth Control Measures (ECM) are implemented to prevent silt from polluting our waterways. In the incidence of exceeded TSS readings, prompt corrective actions are taken to rectify the issue. The Company will continue to work with contractors to increase vigilance in the management of water discharge.

| 1 | Allowable limits for trade effluent discharge (water course for TSS and controlled watercourse for TDS) by NEA |

Managing Vector and Pest Control at Construction Sites

Recognising that construction sites could potentially become environments for mosquito breeding and rodent infestation, the Company works closely with our main contractors to ensure that effective systems are in place to prevent pests and curb dengue transmission around our worksites.

The ISO 45001 occupational health and safety management system and CDL 5-Star EHS Assessment provide a risk management framework to identify and mitigate the risks associated with vector and pest control at construction sites. Apart from ensuring that our contractors schedule and conduct regular housekeeping on-site, we require that they maintain comprehensive pest surveillance and control programmes. We actively engage our contractors and their workers through awareness-building, senior management site visits and educational talks to ensure effective vector control and minimise incurring fines for vector breeding.

Managing Impact on Communities

We provide avenues for the public to raise enquiries or feedback on EHS-related matters. Hotlines managed by our appointed main contractors are made publicly available at all construction sites. Upon receiving EHS-related feedback such as dust or noise disturbance impacting the community, the site management will implement controls in the surrounding area to address the feedback to mitigate the likelihood of further incidences.

In Singapore, NEA regulates the noise levels from construction sites, with a set of permissible noise limits that vary depending on the time of day and type of neighbouring premises. To protect the well-being of nearby residents, our main contractors must comply with the construction noise limits at all our construction sites. To minimise noise-related complaints, our main contractors are encouraged to implement an active management programme and undertake necessary actions to address related complaints. Schedules of the progress at each site are also communicated to the community to apprise them of upcoming works.

EDUCATING EMPLOYEES ON ENVIRONMENTAL MANAGEMENT

The Group believes that environmental awareness and training for employees are catalysts for positive change. We have designed sustainability-related training and content covering topics such as management of energy, water and waste to fulfil the following objectives:

- Build awareness on environmental issues

- Develop shared vision for a sustainable future

- Empower positive actions

We cover various topics including general management and construction management of energy, waste and water. Our employees are introduced to national energy, water and waste management, and the correlations between individual actions, work and the environment.

In 2023, as part of CDL’s company-wide initiative to educate employees on waste management, we have developed and delivered content on CDL’s responsible waste management and disposal techniques for waste generated from our construction sites and managed buildings. This includes sharing on the company’s annual waste reduction targets, the partners and stakeholders we work with to collect, treat, segregate, and recycle waste.

An Enriching Learning Experience at the Sustainable Singapore Gallery and Senoko Waste-to-Energy Incineration Plant

In June 2023, over 50 staff at CDL HQ participated in a guided tour to the Sustainable Singapore Gallery to learn about Singapore’s sustainability efforts and how individuals can contribute to the national effort by reducing, reusing and recycling waste. In July 2023, another 40 staff attended an informative tour at Senoko Waste-to-Energy (WTE) Incineration Plant to learn about WTE incineration process, incinerable items, and the plant operations. These learning journeys reinforced the importance of responsible waste disposal, segregation and recycling and most importantly, encouraged the adoption of a ‘waste less’ mindset.

Exploring waste management through educational trips and seminars

In June 2023, over 50 staff from the Company’s headquarters participated in a guided tour to the Sustainable Singapore Gallery to learn about Singapore’s sustainability efforts and how individuals can contribute to the national effort by reducing, reusing and recycling waste. In July 2023, 40 staff attended an informative tour at Senoko Waste-to-Energy (WTE) Incineration Plant to learn about WTE incineration process, incinerable items, and the plant operations. From September to November 2023, over 350 employees across the Group attended a Group-wide seminar on green building, decarbonisation and safety, which included a dedicated topic on waste management (see details in Human Capital: Training and Development). These learning trips and seminars reinforced the importance of responsible waste disposal, segregation and recycling and most importantly, encouraged the adoption of a ‘waste less’ mindset.

Incidents of Non-compliance

| Indicator | Unit of Measurement | 2019 | 2020 | 2021 | 2022 | 2023 |

| Total number of EHS related non-monetary instances of non-compliance (i.e., SWO) | Number | 2 | 1 | 1 | 5 | 41 |

| EHS Related Fines: CDL Managed Buildings | Number | 0 | 2 | 1 | 0 | 0 |

| EHS Related Fines: CDL Construction Sites | Number | 10 | 8 | 3 | 8 | 7 |

| Total number of EHS related fines and value | Number ($) | 10 (48,000) | 10 (73,500) | 4 (25,200) | 8 (79,500) | 7 (70,000)2 |

| 1 | Three stop-work orders (SWO) were issued to the Company’s main contractors due to vector control by NEA. One safety-related SWO was issued by MOM for demolition activities following the accident at Newport Plaza construction site |

| 2 | Two environmental fines were imposed by the Company’s main contractors across 11 construction/ demolition activities above the noise limit while five environmental fines were imposed for vector control. Three of the total environmental fines received in 2023 were associated to cases in 2022 |

| * | 2022 figures were restated to incorporate electricity use amount from monthly variable charges from building owner |